Description

Number of Pages: 50

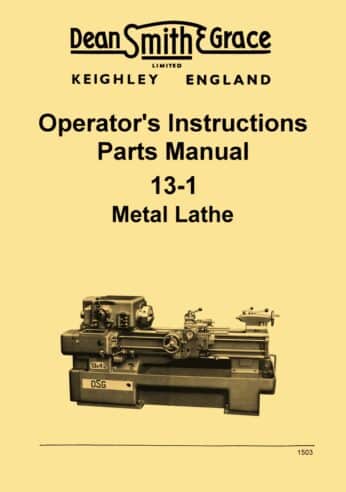

This is a reproduction of an original Asian Metal Lathe 10″x 24″ and 12″x36″ Instructions and Parts Manual. These metal lathes were manufactured in Asia and has been sold under many different names including: JET, Grizzly, Enco, MSC, Acraturn, Frejoth, Shenwai, etc… This manual contains information on setup, lubrication, maintenance, and controls as well as a complete parts list and exploded views and adjustments.

Known models covered:

ENCO 92010

ENCO 110-2021

JET-1024P

JET-1236P

Acraturn TT-1236G

Frejoth F-900 12X36

Frejoth FI-900

Shenwai SW-350 10×24

Shenwai SW-900 12×36

Husky Metal Lathes

|

The manual above may help you operate and maintain your metal lathe. If you would like to learn more about metal lathework techniques, the names and proper uses of different lathe tools, and other lathe operations, I would recommend clicking on the pictures of these two books here. We also have a complete series of different machinist books on sharpening, gearmaking, milling machines, and more here: Workshop Machinist Series |

|

|

|---|

Picture:

Specifications:

Contents:

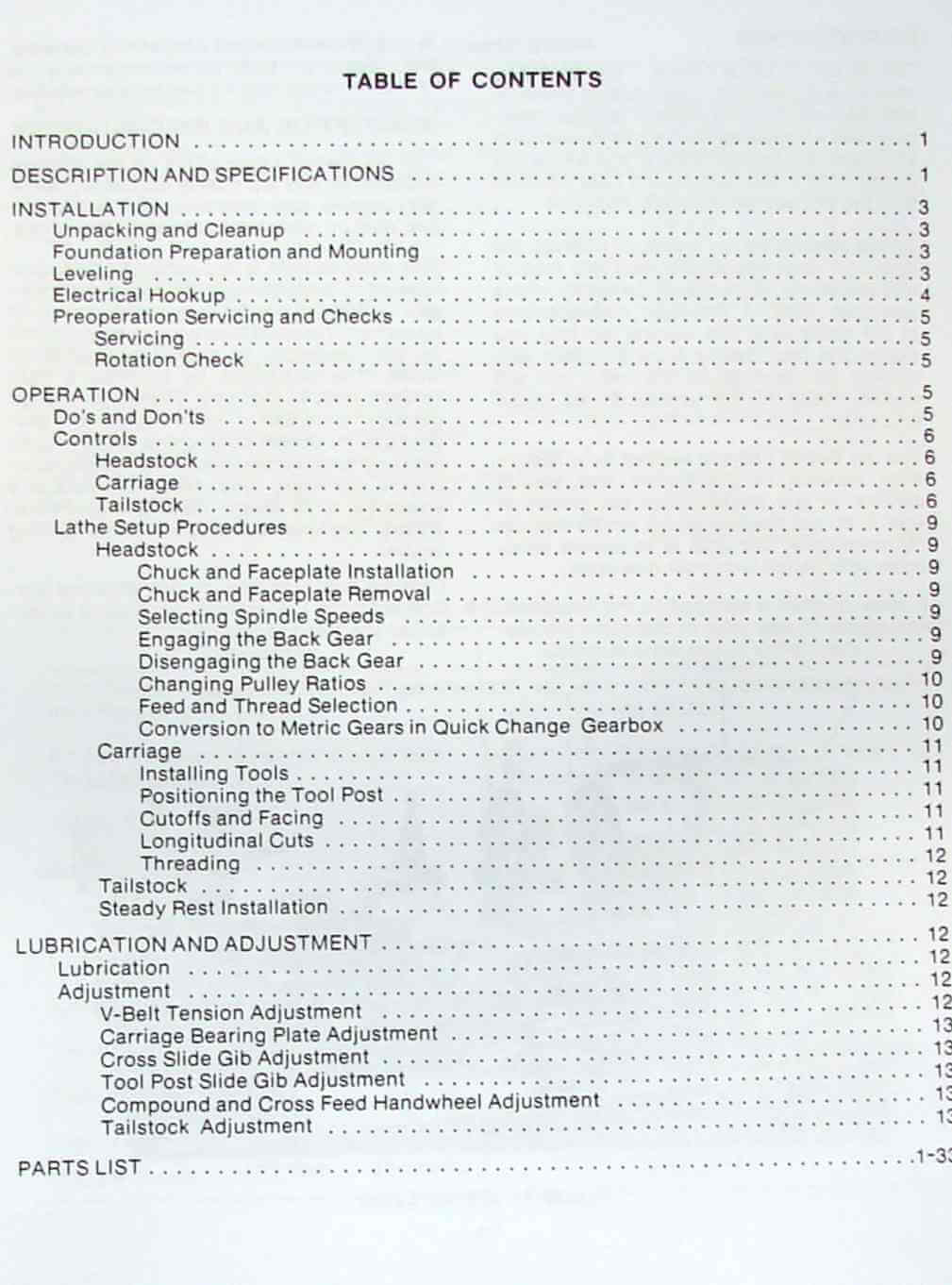

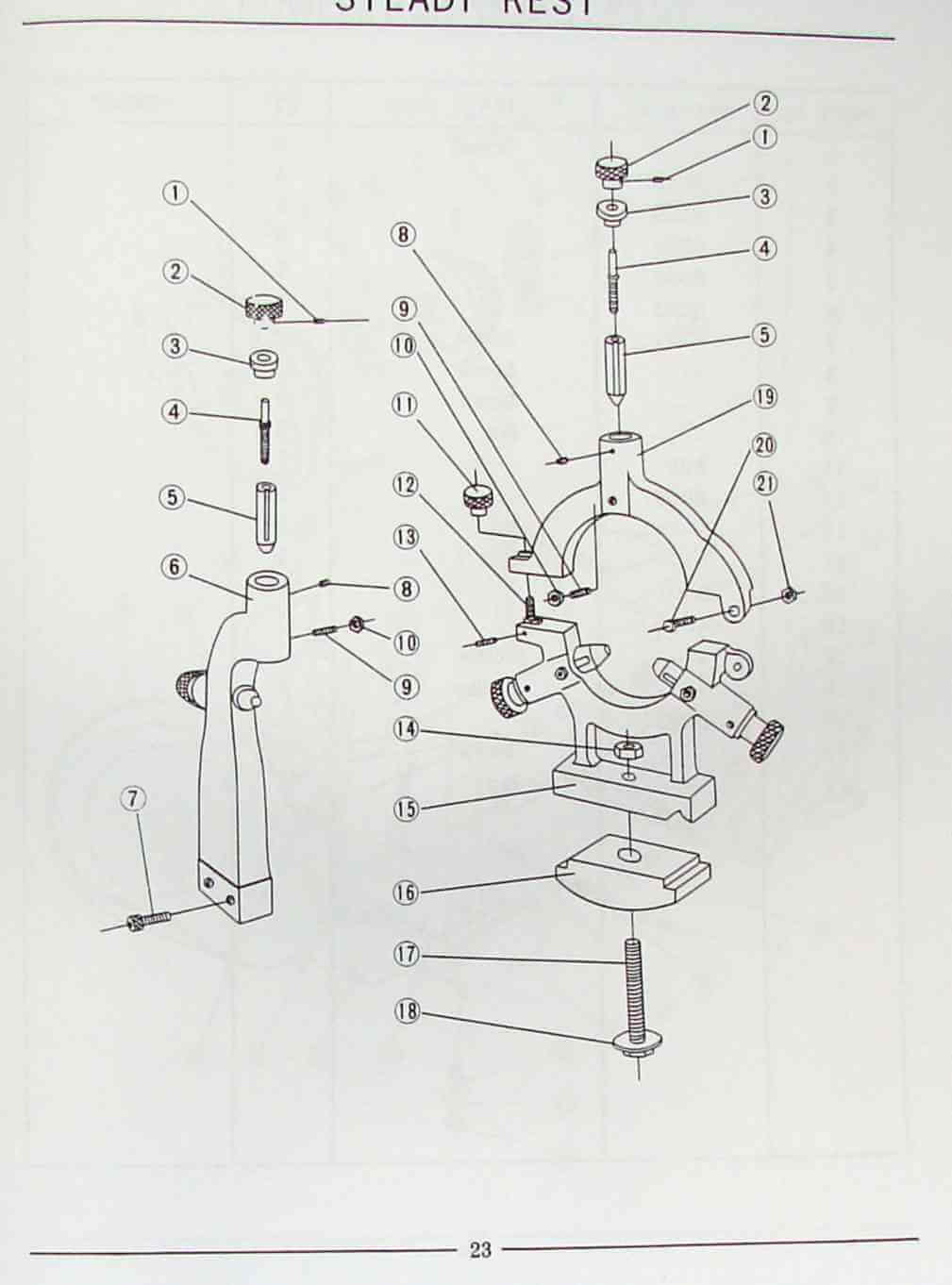

INTRODUCTION.....................................1 DESCRIPTION AND SPECIFICATIONS...................1 INSTALLATION.....................................3 Unpacking and Cleanup............................3 Foundation Preparation and Mounting..............3 Leveling.........................................3 Electrical Hookup................................4 Pre-operation Servicing and Checks...............5 Servicing........................................5 Rotation Check...................................5 OPERATION........................................5 Do's and Don'ts..................................5 Controls.........................................6 Headstock........................................6 Carriage.........................................6 Tailstock........................................6 Lathe Setup Procedures...........................9 Headstock........................................9 Chuck and Faceplate Installation.................9 Chuck and Faceplate Removal......................9 Selecting Spindle Speeds.........................9 Engaging the Back Gear...........................9 Disengaging the Back Gear........................9 Changing Pulley Ratios..........................10 Feed and Thread Selection.......................10 Conversion to Metric Gears in Quick Change Gearbox.........................................10 Carriage........................................11 Installing Tools................................11 Positioning the Tool Post.......................11 Cutoffs and Facing..............................11 Longitudinal Cuts...............................11 Threading.......................................12 Tailstock.......................................12 Steady Rest Installation........................12 LUBRICATION AND ADJUSTMENT......................12 Lubrication.....................................12 Adjustment......................................12 V-Belt Tension Adjustment.......................12 Carriage Bearing Plate Adjustment...............13 Cross Slide Gib Adjustment......................13 Tool Post Slide Gib Adjustment..................13 Compound and Cross Feed Handwheel Adjustment....13 Tailstock Adjustment............................13 PARTS LIST...................................14-50

Overview:

I have collected this information for many years and have found the information they contain to be priceless in using and setting up the machines properly. I believe this manual will be a valuable resource of knowledge that will provide a lot of helpful information that is often hard to find. My manuals are not photocopies. I maintain a high standard of quality in my reproductions. Most of the manuals I reproduce look better than their originals. I have professionally digitally edited every page, and removed stains, wrinkles and handwriting. All of the manuals are printed on thick white paper to withstand shop wear and tear, which is better than a low resolution pdf download.