Description

Number of Pages: 62

This is a reproduction, not a photocopy, of an original Rockwell 14″ Metal Cutting Lathe Instructions and Parts Manual. As you can see from the contents, this is a very detailed manual that covers everything you would want to know about this machine.

This manual covers lots of models.

Known model covered:

25-209

We have two different Rockwell 14″ Metal Lathe manuals.

This manual is for the newer version of the 14″. The major difference between the machines is that the spindle brake and clutch lever is on top of the headstock in the newer version, and the older version has a different type of control for the variable speeds. The other 14″ lathe manual is listed here:

ROCKWELL 14″ Cabinet Metal Lathe Older Operating-Parts Manual

|

The manual above may help you operate and maintain your metal lathe. If you would like to learn more about metal lathework techniques, the names and proper uses of different lathe tools, and other lathe operations, I would recommend clicking on the pictures of these two books here. We also have a complete series of different machinist books on sharpening, gearmaking, milling machines, and more here: Workshop Machinist Series |

|

|

|---|

Contents:

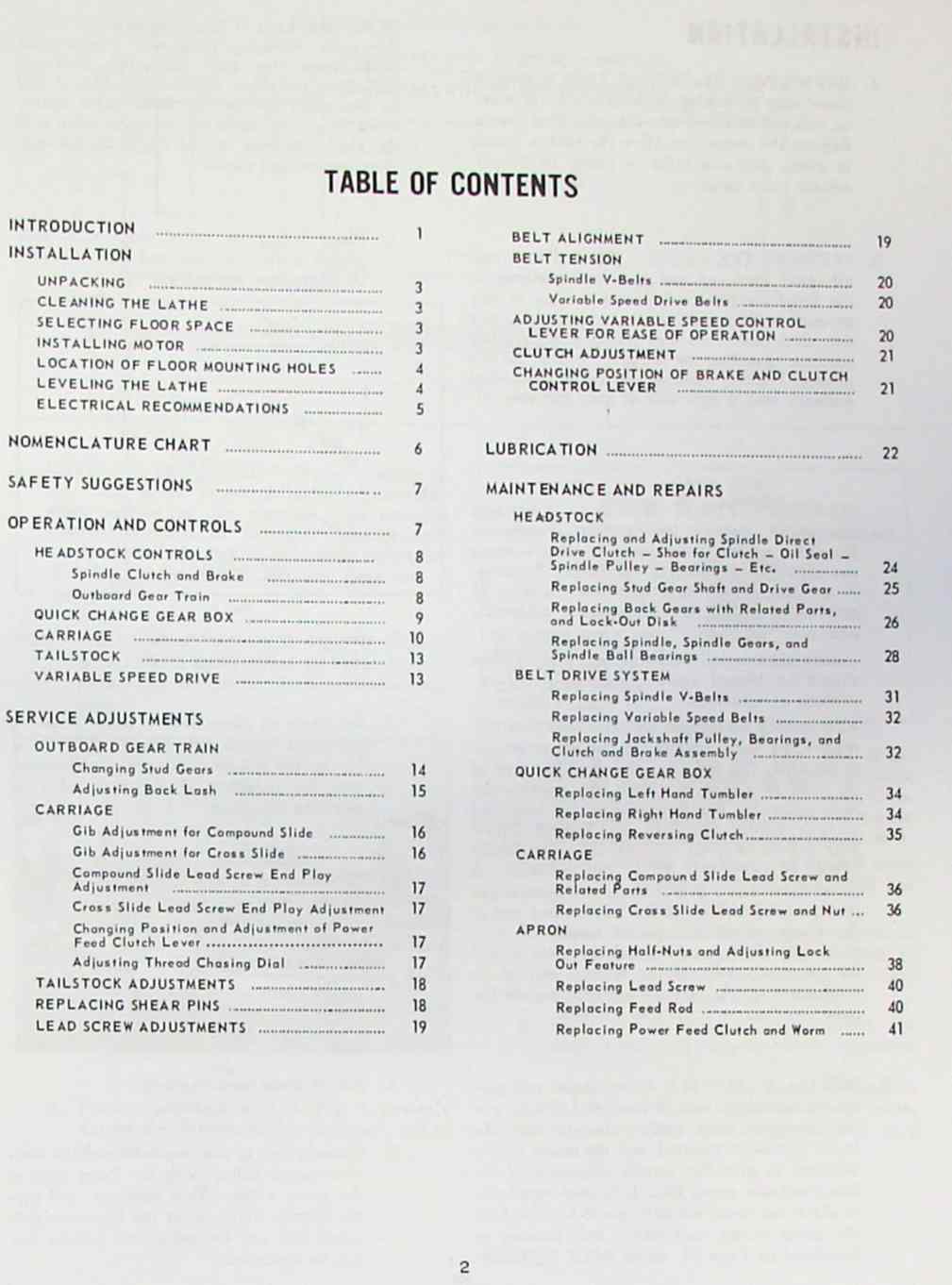

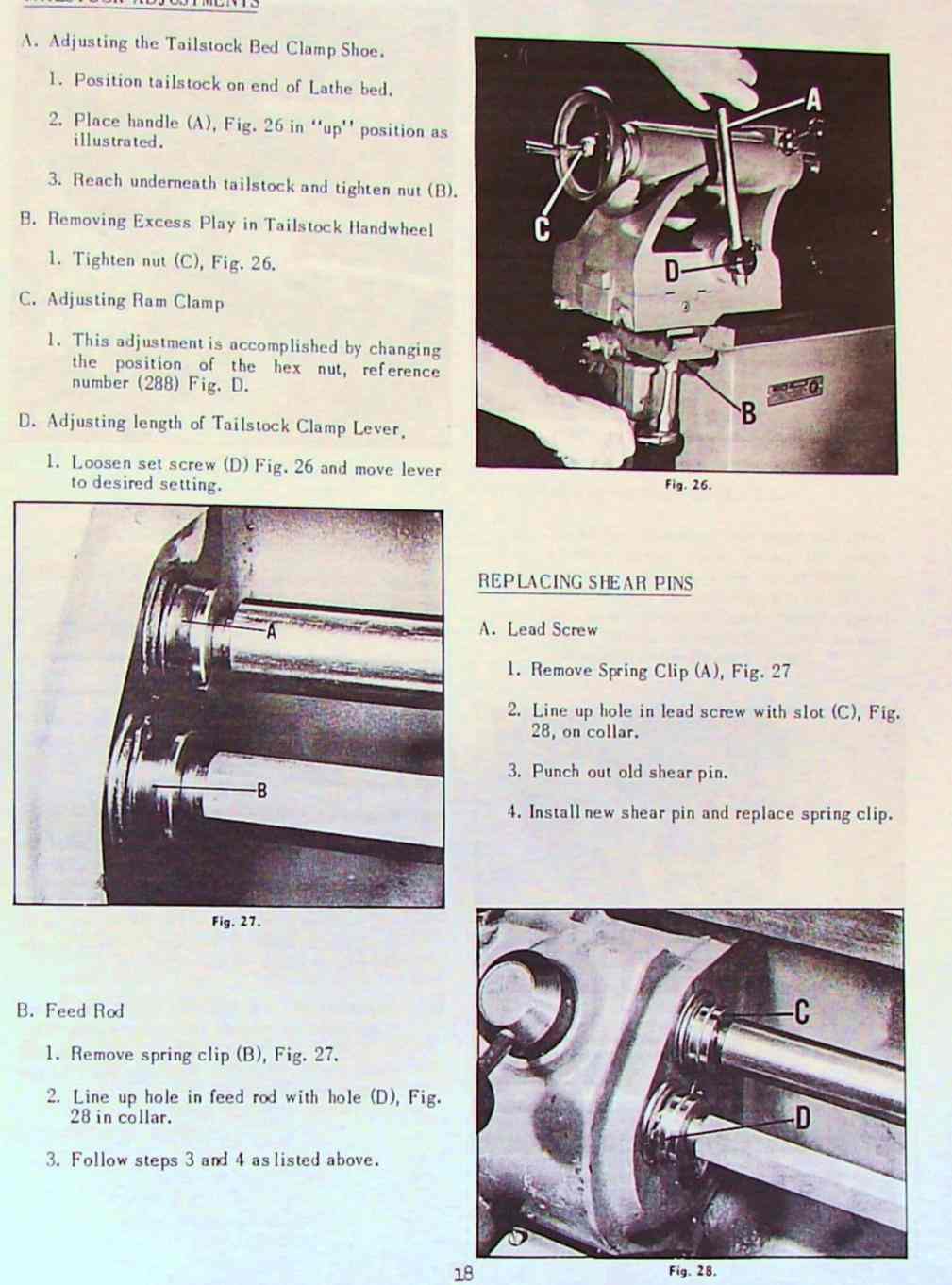

INTRODUCTION .........................................................1 INSTALLATION UNPACKING ............................................................3 CLEANING THE LATHE ...................................................3 SELECTING FLOOR SPACE ................................................3 INSTALLING MOTOR .....................................................3 LOCATION OF FLOOR MOUNTING HOLES .....................................4 LEVELING THE LATHE ...................................................4 ELECTRICAL RECOMMENDATIONS ...........................................5 NOMENCLATURE CHART ...................................................6 SAFETY SUGGESTIONS ...................................................7 OPERATION AND CONTROLS ...............................................7 HEADSTOCK CONTROLS ...................................................8 Spindle Clutch and Brake .............................................8 Outboard Gear Train ..................................................8 QUICK CHANGE GEAR BOX ................................................9 CARRIAGE ............................................................10 TAILSTOCK ...........................................................13 VARIABLE SPEED DRIVE ................................................13 SERVICE ADJUSTMENTS OUTBOARD GEAR TRAIN Changing Stud Gears .................................................14 Adjusting Back Lash .................................................15 CARRIAGE Gib Adjustment for Compound Slide ...................................16 Gib Adjustment for Cross Slide ......................................16 Compound Slide Lead Screw End Play Adjustment ..........................................................17 Cross Slide Lead Screw End Play Adjustment...........................17 Changing Position and Adjustment of Power Feed Clutch Lever....................................................17 Adjusting Thread Chasing Dial........................................17 TAILSTOCK ADJUSTMENTS ...............................................18 REPLACING SHEAR PINS ................................................18 LEAD SCREW ADJUSTMENTS ..............................................19 BELT ALIGNMENT ......................................................19 BELT TENSION Spindle V-Belts .....................................................20 Variable Speed Drive Belts ..........................................20 ADJUSTING VARIABLE SPEED CONTROL LEVER FOR EASE OF OPERATION .........................................20 CLUTCH ADJUSTMENT ...................................................21 CHANGING POSITION OF BRAKE AND CLUTCH CONTROL LEVER .......................................................21 LUBRICATION .........................................................22 MAINTENANCE AND REPAIRS HEADSTOCK Replacing and Adjusting Spindle Direct Drive Clutch-Shoe for Clutch-Oil Seal-Spindle Pulley-Bearings-Etc.....................................24 Replacing Stud Gear Shaft and Drive Gear ............................25 Replacing Back Gears with Related Parts, and Lock-Out Disk ...................................................26 Replacing Spindle, Spindle Gears, and Spindle Ball Bearings ...............................................28 BELT DRIVE SYSTEM Replacing Spindle V-Belts ...........................................31 Replacing Variable Speed Belts ......................................32 Replacing Jackshaft Pulley, Bearings, and Clutch and Brake Assembly..32 QUICK CHANGE GEAR BOX Replacing Left Hand Tumbler .........................................34 Replacing Right Hand Tumbler ........................................34 Replacing Reversing Clutch...........................................35 CARRIAGE Replacing Compound Slide Lead Screw and Related Parts ...............36 Replacing Cross Slide Lead Screw and Nut ............................36 APRON Replacing Half-Nuts and Adjusting Lock Out Feature .........................................................38 Replacing Lead Screw ................................................40 Replacing Feed Rod ..................................................40 Replacing Power Feed Clutch and Worm ................................41

Overview:

I have collected this information for many years and have found the information they contain to be priceless in using and setting up the machines properly. I believe this manual will be a valuable resource of knowledge that will provide a lot of helpful information that is often hard to find. My manuals are not photocopies. I maintain a high standard of quality in my reproductions. Most of the manuals I reproduce look better than their originals. I have professionally digitally edited every page, and removed stains, wrinkles and handwriting. All of the manuals are printed on thick white paper to withstand shop wear and tear.